PRODUCTS

Steel Plate

Steel Coil

Steel Pipe

Steel Rod

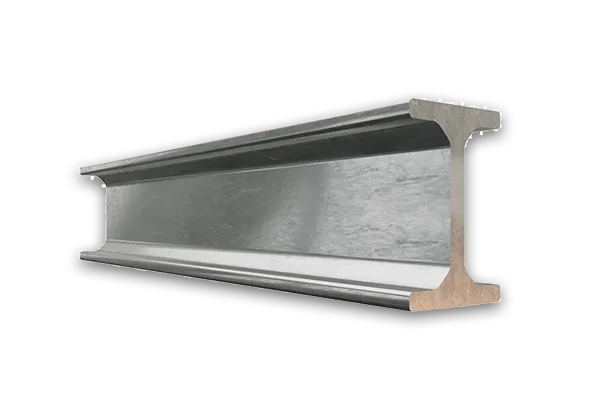

Steel Profiles

Steel Rebar

Wire Rod

Aluminum

Copper

A36/Q235/S235JR Carbon Steel Plate

A36 is a low-carbon steel containing trace amounts of manganese, phosphorus, sulfur, silicon and other elements such as copper. A36 has good weldability and high yield strength, and is the structural steel plate specified by the engineer. ASTM A36 steel plate is often manufactured into a variety of structural steel parts. This grade is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its low yield point, A36 carbon plate can be used to design lighter weight structures and equipment, and provide good weldability. Construction, energy, heavy equipment, transportation, infrastructure and mining are the industries where A36 panels are commonly used.

MORE304L is one of the austenitic stainless steels with a chromium content of at least 18%, a nickel content of at least 8%, and a maximum carbon content of 0.03. 304L stainless steel is an ideal choice for various household and commercial applications, with excellent corrosion resistance, ease of manufacturing and excellent formability. Austenitic stainless steels are also considered to be the easiest to weld among high alloy steels and can be welded by all fusion and resistance welding processes.

MOREASTM A633 steel includes four grades: A, C, D, and E, of which the thickness of grade C can reach 4 inches and the thickness of grade E can reach 6 inches. ASTM A633 steel specification is based on the standard specification for standardized high-strength low-alloy structural steel plate, which requires high notch toughness under low temperature conditions.

MOREPrepainted Galvanized Steel Sheet

When steel components are used to make more complex finished products, they can be galvanized before the product is assembled. This is called pre-galvanizing, or "pre-galvanizing". It may also be referred to as "in-line", "continuous" or "rolled" galvanizing. Essentially, steel components (such as sheets or wires) are galvanized using an automated process before they are cut to size.

MOREABOUT US

Established in 2005, we are a key steel manufacturer boasting a 400,000㎡ production site and an annual output of 2.5 million tons. Our offerings span mild steel, alloy plates, coated steel coils, and welded pipes, serving industries like machinery, shipbuilding, and infrastructure.

Certified by ISO 9001, SGS, and API, we guarantee top-tier quality and safety. Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service.

Founded in 2005

Annual production capacity reaches 2.5 million tons

Owns a 400,000 square meter production facility

Market coverage covers over 25 countries

APPLICATION

Ship

Chemical Industry

Electricity

Oil and gas transportation

WHY CHOOSE US

Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service.

Quality

Certified by ISO 9001, SGS, and API, we guarantee top-tier quality and safety.

Qualifications

Our market reach covers 25+ nations, with a focus on building enduring client partnerships through consistent supply and responsive service.

Equipment

we are a key steel manufacturer boasting a 400,000㎡ production site and an annual output of 2.5 million tons.

BLOG

Dedicated to progress and eco-friendliness, we prioritize tech upgrades and low-carbon production to fuel sector development.

Carbon Steel Plate: A Panoramic Analysis of Performance, Applications, and Industry Development

Carbon steel plate, one of the most widely used metal materials in modern industry, is composed of iron as its base and carbon as its primary alloying element. Its adjustable strength, excellent workability, and high cost-effectiveness have made it ubiquitous in numerous fields, including construction, machinery, automotive, and energy. From everyday steel structures to core components of heavy machinery, carbon steel plate has always played a crucial role as the "cornerstone of industry." This article will begin with its definition and classification, systematically analyzing its performance characteristics, production processes, and application scenarios, and also provide an outlook on industry development trends, providing a comprehensive reference for practitioners and enthusiasts.

Carbon Steel Coil: Characteristics, Processing, and Applications

In the steel industry, carbon steel coil is a basic steel product in coiled form, based on an iron-carbon alloy. Due to its abundant raw materials, mature production process, and high cost-effectiveness, it has become an indispensable key material in industrial manufacturing, construction, and other fields. Compared to flat carbon steel plates, carbon steel coils are more convenient for continuous transportation, storage, and subsequent processing, significantly improving production efficiency. Therefore, they are widely used in large-scale production scenarios.